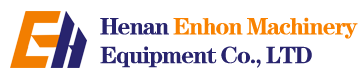

Features

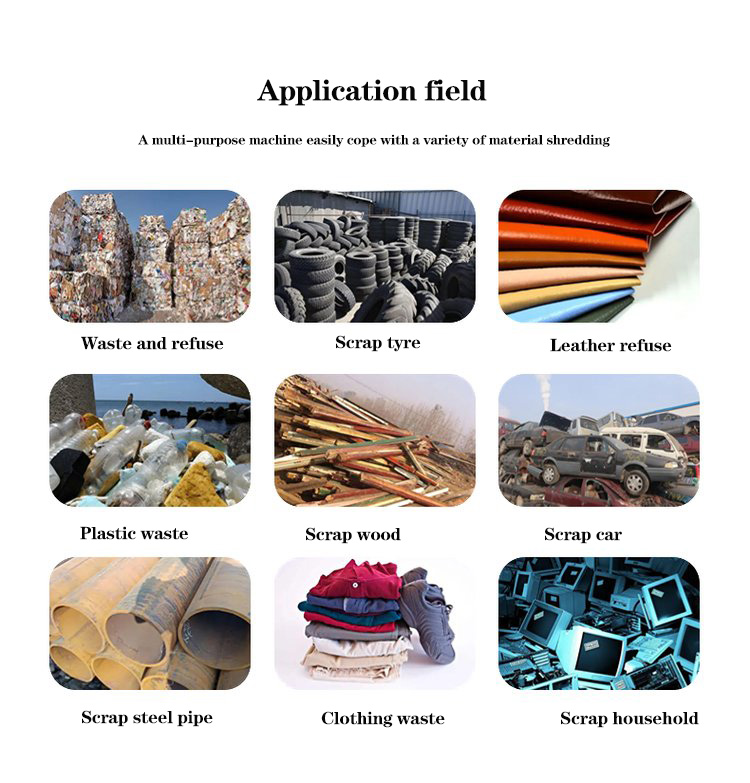

Scrap steel shredder blade is made of high strength alloy steel, has strong wear resistance and high strength and other characteristics, differential operation between shafts, tearing, extrusion, bite and other functions, professional design for broken metal, with uniform discharge, large output, low noise and other advantages.

Working Rrinciple:

Scrap steel shredder blade is made of high strength alloy steel, has strong wear resistance and high strength and other characteristics, differential operation between shafts, tearing, extrusion, bite and other functions, professional design for broken metal, with uniform discharge, large output, low noise and other advantages.

Product Advantages:

1, the use of "motor + reducer" drive design, to provide large shear force, to ensure higher crushing efficiency. It is often used for the fine crushing of solid waste, and the material can be processed to a smaller particle size at one time.

2, the torsion arm type hydraulic press device can push the material smoothly and effectively to the crushing area; Hydraulic auxiliary maintenance door, hydraulic auxiliary screen open, closed structure open with a key, the greater convenience of the tool, screen replacement, repair and maintenancework. ;

3, combined screen structure design, can be independently replacedaccording to the use of conditions, effectively reducing maintenance costs.

4, each knife can be independently disassembled and installed, can be quickly disassembled in a short time, greatly reducing the workload of workers, improve the continuity of production.

Technical Data:

Model | Overall dimensions (L W H)(mm) | Crushing chamber size (mm) | Blade diameter (mm) | Blade thickness (mm) | Number of blades (pieces) | Power (kw) | Weight (kg) |

EH-500 | 2800×1300×1850 | 500×480 | 200 | 20 | 24 | 11×2 | 2200 |

EH-800 | 3000×1300×1850 | 800×480 | 200 | 20 | 40 | 15×2 | 2500 |

EH-1000 | 3300×1900×2200 | 1000×690 | 300 | 40 | 24 | 22×2 | 5200 |

EH-1200 | 3600×2000×2200 | 1200×690 | 300 | 40 | 30 | 30×2 | 6400 |

EH-1500 | 4180×2100×2400 | 1500×850 | 550 | 50/75 | 30/20 | 55×2 | 9000 |

EH-1800 | 5800×2400×3300 | 1800×1206 | 550 | 50/75 | 36/24 | 75×2 | 13600 |

EH-2000 | 6400×2700×3500 | 2000×1490 | 600 | 50/75 | 40/26 | 90×2 | 20100 |

EH-2500 | 7500×3200×3800 | 2500×1800 | 600 | 75/100 | 32/24 | 110×2 | 25000 |

EH-3000 | 8600×3500×4000 | 3000×1800 | 600 | 75/100 | 40/30 | 160×2 | 31000 |

Remark:1.The number, diameter and thickness of blade claws can be customized according to the type of material and discharge size; 2. Different types of materials and discharge sizes, equipment output will be differen | |||||||