Features

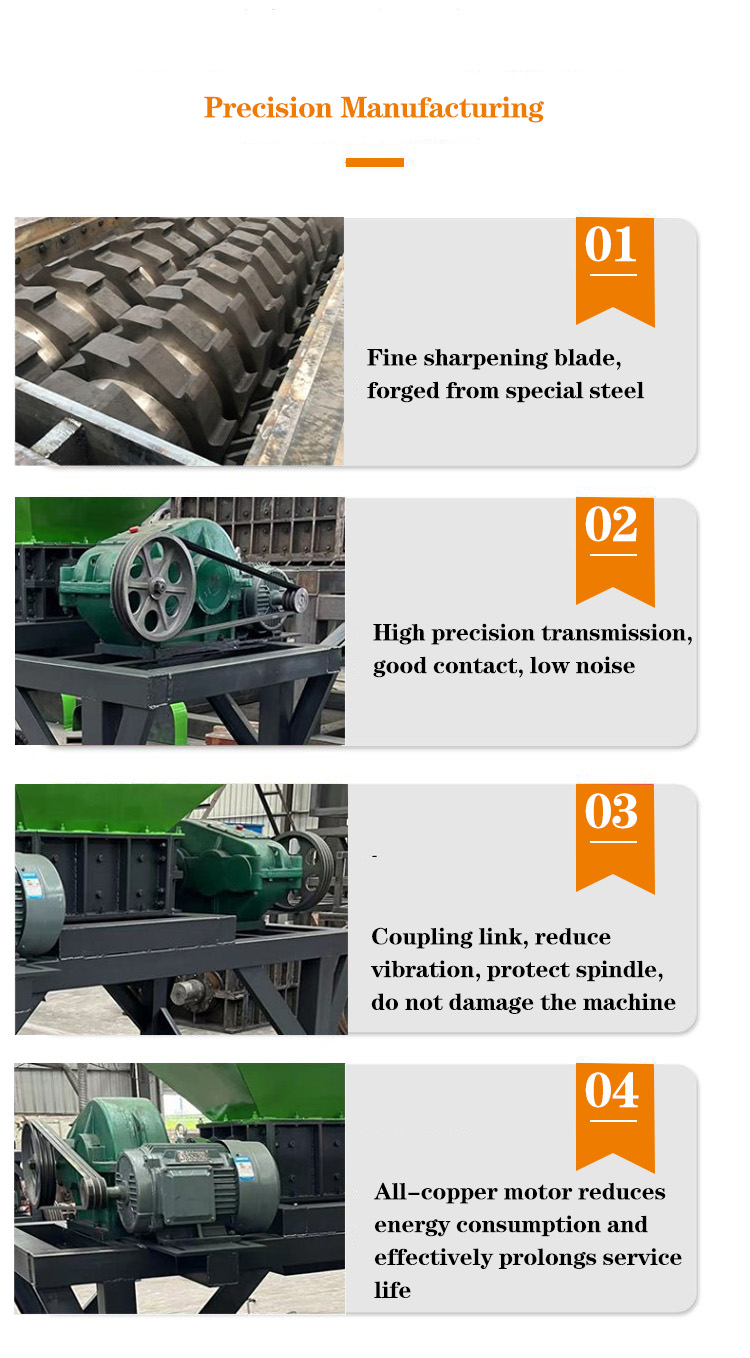

Metal shredder can be divided into two-axis metal shredder, single-axis metal shredder, four-axis metal shredder. The main function of the metal shredder is to squeeze large pieces of metal materials and large diameter drums of metal materials that are inconvenient to transport through the shear of the metal shredder to crush each other into sheet materials that meet the requirements. Large metal shredder not only improves the production capacity and crushing efficiency, but also expands the scope of application. The large metal shredder produced by our company is an excellent fine crushing machinery, the series of large metal shredder products in absorbing a variety of crusher advantages on the basis of the full use of impact, shear, mutual impact, grinding and other theories carefully developed.

Metal shredder main components: shredding blade group, bearing box, box bracket, feeding system, power system, electrical control system. Metal shredder is mainly used for shredding thin and light metal with a certain strength to increase its packing density in order to facilitate transportation and recycling. Shred objects such as metal barrels, refrigerators, cars, scrap steel, steel furniture, etc.

Working Rrinciple:

Metal shredder is composed of motor, hard gear reducer, rotary tool shaft, moving tool, fixed tool, frame, frame, box, working platform and other main structures. Double axis metal shredder frame fixed knife, rotary knife shaft is equipped with removable embedded knife, knife number according to different models and the size of the rotary knife shaft, and the knife is a four-corner surface can be used knife, with blunt after removal to replace the Angle, until the knife is blunt after sharpening, because it is claw knife, rotary cutting, and fixed knife and knife is SKD11 material, After heat treatment, the hardness reaches more than 60° HRC, so the service life is long, the cutting ability is strong, the production capacity is high, and the normal use of more than 1000 tons must be sharpened. Dual-axis metal shredder can be controlled by PLC programmable, with high degree of automation and easy operation.

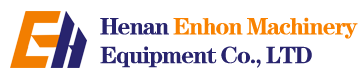

Product Advantages:

1, heavy knife, high crushing efficiency, tools are cast by alloy steel, strong long service life.

2, the frame plate is thick, can resist high torque, very strong.

3, microcomputer (PLC) automatic control, set up start, stop, reverse and overload automatic reverse control function.

4, the equipment has the characteristics of high speed, large torque, low noise, dust can meet the environmental protection standards.

5, easy to adjust, low maintenance costs, economic and durable.

6, the thickness of the tool and the number of claws can be changed according to different materials.

7, the use of high-strength heavy-duty special steel processing refining, more reasonable with the tool to provide a powerful power for cutting.

8, the main body of the equipment adopts high-quality steel plate welding stress relief treatment/overall machining to ensure the stability of the equipment in the long-term heavy load.

Technical Data:

Model | Overall dimensions (L W H)(mm) | Crushing chamber size (mm) | Blade diameter (mm) | Blade thickness (mm) | Number of blades (pieces) | Power (kw) | Weight (kg) |

EH-500 | 2800×1300×1850 | 500×480 | 200 | 20 | 24 | 11×2 | 2200 |

EH-800 | 3000×1300×1850 | 800×480 | 200 | 20 | 40 | 15×2 | 2500 |

EH-1000 | 3300×1900×2200 | 1000×690 | 300 | 40 | 24 | 22×2 | 5200 |

EH-1200 | 3600×2000×2200 | 1200×690 | 300 | 40 | 30 | 30×2 | 6400 |

EH-1500 | 4180×2100×2400 | 1500×850 | 550 | 50/75 | 30/20 | 55×2 | 9000 |

EH-1800 | 5800×2400×3300 | 1800×1206 | 550 | 50/75 | 36/24 | 75×2 | 13600 |

EH-2000 | 6400×2700×3500 | 2000×1490 | 600 | 50/75 | 40/26 | 90×2 | 20100 |

EH-2500 | 7500×3200×3800 | 2500×1800 | 600 | 75/100 | 32/24 | 110×2 | 25000 |

EH-3000 | 8600×3500×4000 | 3000×1800 | 600 | 75/100 | 40/30 | 160×2 | 31000 |

Remark:1.The number, diameter and thickness of blade claws can be customized according to the type of material and discharge size; 2. Different types of materials and discharge sizes, equipment output will be differen | |||||||