Features

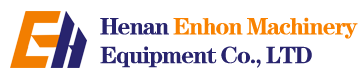

Bicycle crusher is mainly used for crushing cans, grinding steel tile, scrap car crushing, paint bucket crushing, iron filings crushing and other scrap metal recycling crushing processing. The fine processing of scrap metal is realized so as to achieve better profit prospects in terms of transport cost and recovery price of scrap metal. In the structure of the equipment, the main body shell is made of extra-thick steel plate, and the inner liner is high manganese cast steel to protect the external body. In the rotor part of the main body, the machine adopts a disc type tight rotating mechanism, and several steel plates are installed on the horizontal axis on the rotor (the number and diameter of the steel plates are based on the model), and the circumference of the steel plate is distributed with 6 pins. The axial suspension has a number of hammer heads for crushing the material, the main shaft is supported by ball bearings, the circulating oil is forced to lubricated and cooled, and the temperature sensor is equipped to ensure the high-speed and stable operation of the equipment, and the scrap crushing operation is completed through the coordination of the above shell and the main shaft.

Working Rrinciple:

The core principle of the automobile crusher is to use a hammer to hit metal materials. Driven by the high-speed high-torque motor, the hammer head on the rotor of the main engine takes turns to hit the objects to be broken into the chamber, and tears the objects to be broken into the specifications through the space formed between the liner plate and the hammer head. According to the working condition of the crusher, it can be divided into dry system, wet system and semi-wet system. The dry system mainly refers to the broken material must pass through the air rotation sorting system to separate the metal and non-metal, and the whole system is equipped with a dust removal device. The wet system means that water is sprayed at the same time of crushing, and water is washed at the same time of sorting. The semi-wet system is only sprayed with a small amount of water to prevent dust when it is broken, and there is no cleaning.

Product Advantages:

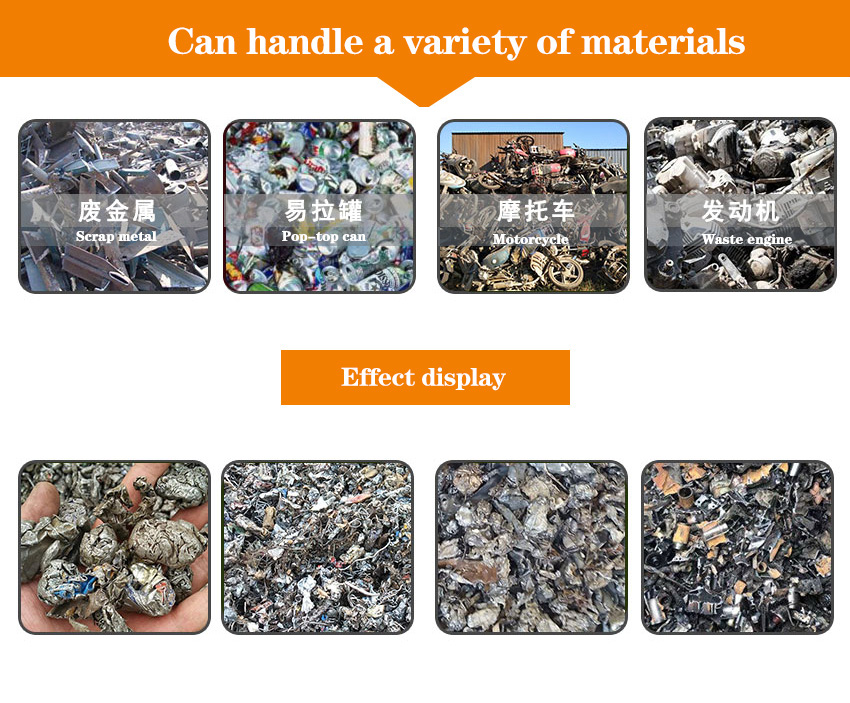

1. The fuselage is reinforced with extra-thick steel plate and diagonal brace to ensure that the equipment can meet the overload operation;

2. The lining plate and hammer head are processed by heat treatment to eliminate stress naturally, the chemical composition is more stable, and the service life is increased by more than 30%;

3. The press device precompresses the material, expands the feeding range and improves the production efficiency.

4. Set the safety door, after the unbreakable material enters the crushing chamber, the operator can open the safety door and discharge it from the body to avoid damaging the crusher.

5. Hydraulic cover opening device, save time and labor to replace and repair;

6.PLC control system and hydraulic power system, intelligent production save time and labor, equipment operation at a glance.

Technical Data:

型号 | 进料口尺寸 (mm) | 出料粒度 (mm) | 产量 (t) | 功率 (kw) | 重量 (t) | 外形尺寸 (mm) |

600 | 500×600 | 10-40 | 0.5-1 | 18.5 | 2.2 | 1720×660×1850 |

800 | 700×800 | 10-50 | 1-1.5 | 30 | 3.6 | 1910×850×1990 |

1000 | 900×1000 | 14-70 | 2-3 | 75 | 6.5 | 2000×1070×1990 |

1200 | 1000×1200 | 20-70 | 3-5 | 90 | 10 | 2400×1090×2270 |

1600 | 1200×1600 | 20-100 | 4-6 | 110 | 18 | 3240×1730×3630 |

1800 | 1200×1800 | 20-120 | 5-8 | 132 | 24 | 3620×1910×3870 |

2000 | 1200×2000 | 20-140 | 7-10 | 160 | 37 | 4140×2230×4279 |