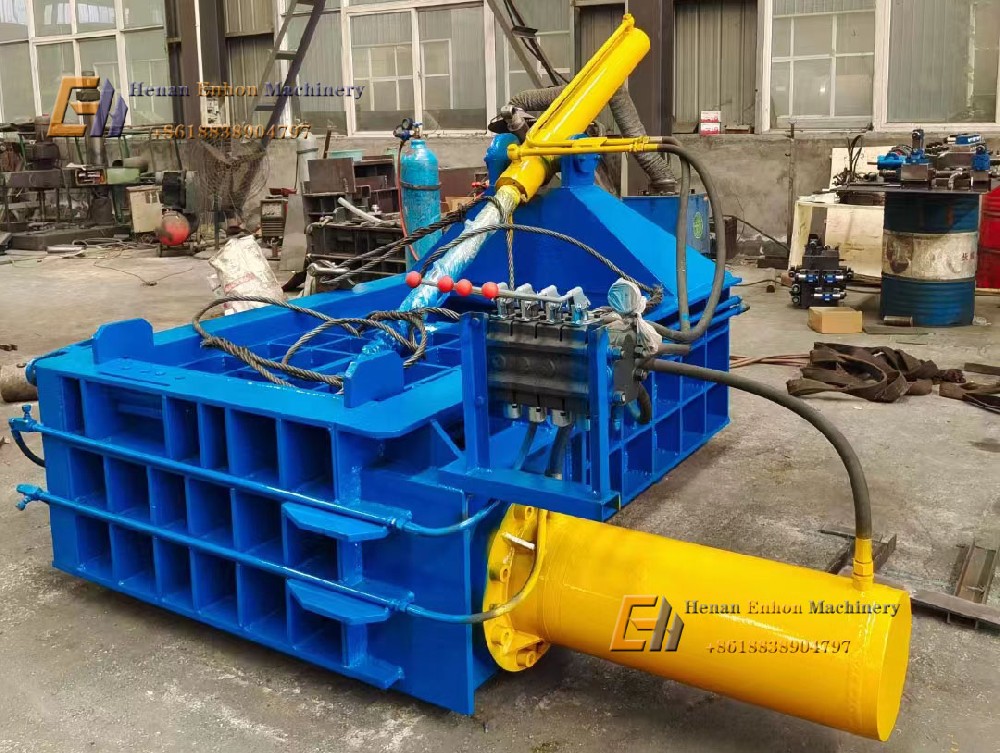

Features

The basic principle of the hydraulic metal press is to use the metalmaterial under the action of external force, can produce plastic deformation of the property, to the metal material with enough, can gather and produce deformation of the external force, so as to form a tight bundle. Therefore,plastic deformation can not be produced, or plastic deformation is very small metal, can not be directly packaged. Such as high carbon steel, tool steel, wire rope and cast iron, etc., can not be directly installed for packaging.

Working Rrinciple:

Scrap iron stamping machine is mainly used in recycling processing industry and metal smelting industry. All kinds of metal scraps, steel shavings, scrap steel, scrap iron, scrap copper, scrap aluminum, aluminum shavings, disassembled car shells, waste oil barrels and other metal raw materials can be squeezed into cuboid, cylinder and other shapes of qualified charge, easy storage, transportation and recycling, improve furnace casting speed, improve labor efficiency, reduce transportation, manpower, smelting costs.

Product Advantages:

1, the use of hydraulic drive, smooth work without noise, extrusion speed, large density of the package, transport process is not easy to scatter;

2, the material box is welded with high quality steel plate, the mechanical parts are durable, the failure rate is low, the service life is long;

3, the equipment is equipped with cooling system, the continuous working capacity of scrap steel press, reduce the incidence of failure, the cooling system is mainly water-cooled;

4, cylinder seals using domestic high quality seals, quality assurance, strong pressure resistance, can achieve long-term use without aging without wear;

5, installation without foot screws, covers a small area, no foundation;

6, the operation mode can be broken up and automatic mode, simple operation, a study will be;

7, direct pressing molding, no need for other processes, will not change the metal material, increase the utilization rate;

8, where there is no power supply, diesel engine can be used as power;

9, the discharging form is: side turning bag, side pushing bag, forward pushing bag or no bag four ways, high safety factor, safer than the traditional baler.

Technical Data:

Equipment model | Pressure(ton) | Press bin size(mm) | Bales size(cm) | Press time(s) | Power(kW) |

EH-Y81-125 | 125 | 1200*800*500 | 30*30 | 100 | 15 |

EH-Y81-135 | 135 | 1200*1000*600 | 30*30 | 110 | 18.5 |

EH-Y81-160 | 160 | 1200*1000*600 | 35*35 | 110 | 18.5 |

EH-Y81-180 | 180 | 1600*1200*800 | 40*40 | 130 | 22 |

EH-Y81-200 | 200 | 1600*1200*800 | 50*50 | 140 | 22+15 |

EH-Y81-250 | 250 | 2000*1750*1000 | 50*50 | 150 | 44 |

EH-Y81-315 | 315 | 2500*2000*1200 | 50*50 | 170 | 60 |

EH-Y81-400 | 400 | 3000*2500*1200 | 60*60 | 180 | 90 |