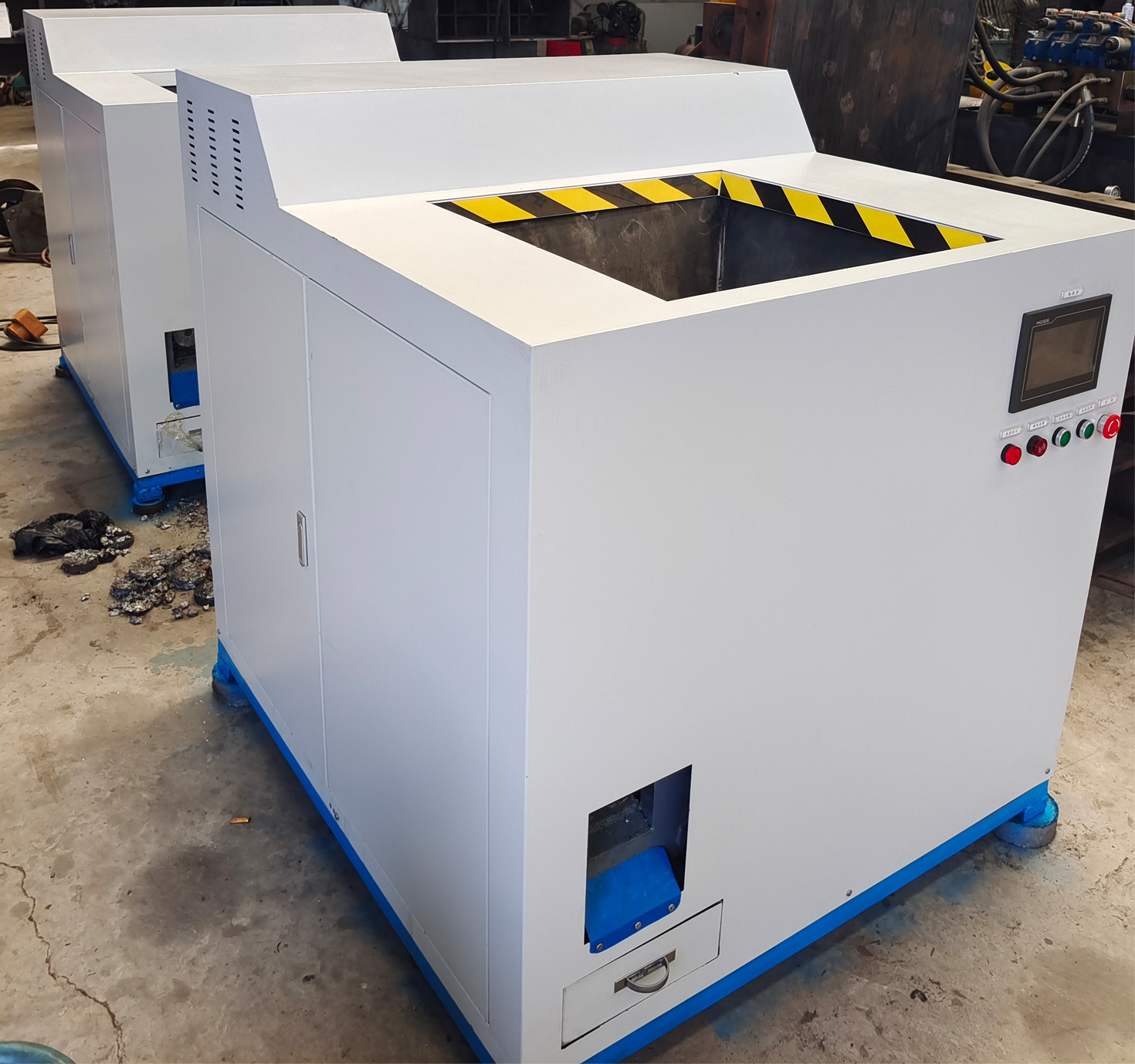

Features

The metal chip press can compress the scrap metal chips into a cake shape using the hydraulic principle, and the chip oil in the scrap metal chips can be separated and collected during the compression process. In order to avoid the splashing of chip oil everywhere during the compression process, the metal chip cake press adopts a closed structure, which can realize the cleanliness of the factory environment during the oil removal process of scrap metal chip cake.

Working Rrinciple:

In the exemption clause of hazardous waste, it is stated that oily metal chips need to be pressed, filtered, filtered to remove oil until it is static without dripping, packed and pressed, and used for metal smelting before they can be used in the process of exemption. Therefore, in the treatment process of oily metal chips, metal chip cake press has become the choice of many machining bosses.

Product Advantages:

The metal chip press can compress the scrap metal chips into a cake shape using the hydraulic principle, and the chip oil in the scrap metal chips can be separated and collected during the compression process. In order to avoid the splashing of chip oil everywhere during the compression process, the metal chip cake press adopts a closed structure, which can realize the cleanliness of the factory environment during the oil removal process of scrap metal chip cake.

Technical Data:

Equipment model | Pressure(ton) | Press bin size(mm) | Bales size(cm) | Press time(s) | Power(kW) |

EH-Y81-125 | 125 | 1200*800*500 | 30*30 | 100 | |

EH-Y81-135 | 135 | 1200*1000*600 | 30*30 | 110 | 18.5 |

EH-Y81-160 | 160 | 1200*1000*600 | 35*35 | 110 | 18.5 |

EH-Y81-180 | 180 | 1600*1200*800 | 40*40 | 130 | 22 |

EH-Y81-200 | 200 | 1600*1200*800 | 50*50 | 140 | 22+15 |

EH-Y81-250 | 250 | 2000*1750*1000 | 50*50 | 150 | 44 |

EH-Y81-315 | 315 | 2500*2000*1200 | 50*50 | 170 | 60 |

EH-Y81-400 | 400 | 3000*2500*1200 | 60*60 | 180 | 90 |